Product parameters:

| Model | PT-ZT20 |

| Stroke (mm) | 200(XY) |

| Load (kg) | 10 |

| Resolution (um) | 0.05 |

| Minimum step size (um) | 0.2 |

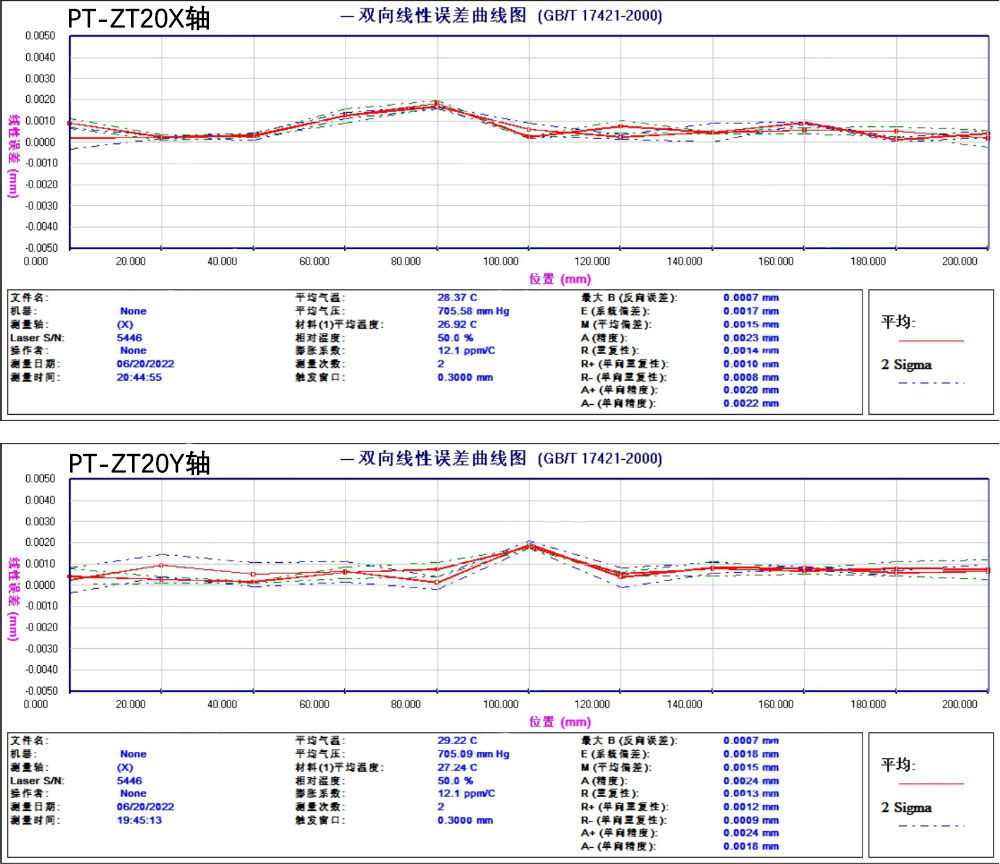

| Unidirectional repeat positioning accuracy/guaranteed value (um) | ±0.5 or 1 |

| Unidirectional repeat positioning accuracy/typical value (um) | ±0.3 or 0.6 |

| Bidirectional repeat positioning accuracy/guaranteed value (um) | ±1 or 2 |

| Bidirectional repeat positioning accuracy/Typical value (um) | ±0.5 or 1 |

| Positioning accuracy/Guaranteed value (um) | ±2 or 4 |

| Positioning accuracy/Typical value (um) | ±1 or 2 |

| Maximum speed (mm/s) | 500 |

| Straightness (um) | 10 |

| Flatness (um) | 10 |

| Offset pendulum | 20 |

| Pitch and pitch | 20 |

| Weight (kg) | 32 |

※ Note

[1] : Center vertical load when placed horizontally.

[2] : The minimum motion increment is not equivalent to resolution. The minimum motion increment refers to the smallest amount that a motion system can move under continuous and stable conditions. Generally speaking, the system resolution is much smaller than the minimum motion increment. Considering the influence of the transmission structure and the encoder on the system error, compared with the stepping motor displacement stage, the minimum motion increment of the linear motor displacement stage is closer to the resolution.

[3] : The precision measurement data is the data measured by a laser interferometer when the platform is placed horizontally.

[4] : The distinction between typical values and guaranteed values can be found in the technical guide.

[5] : The maximum speed is a typical value and may vary depending on the load and controller.

Product Details:

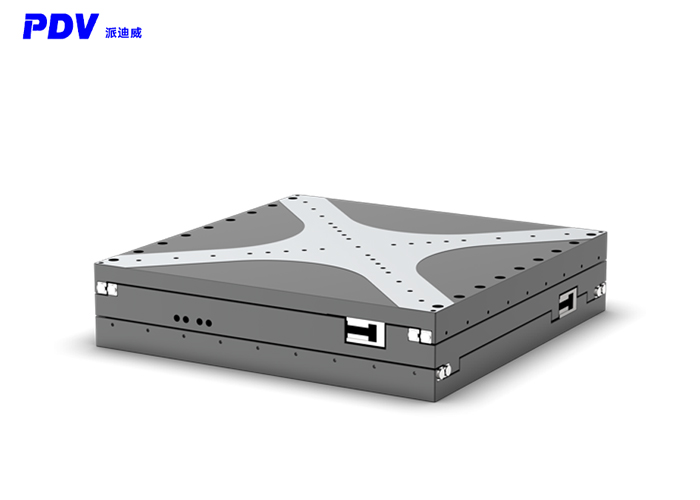

High precision, integrated design, flexible integration

The linear motor two-dimensional scanning platform is specially designed for laboratory and industrial applications that require high-precision two-dimensional positioning. The platform is driven by linear motors and features high precision, high stability, and low noise. It adopts an integrated design that is easy to integrate and offers multiple stroke and configuration options to meet diverse application requirements.

Main features:

The stroke, precision and load-bearing capacity can all be customized to meet personalized demands: The platform's stroke, precision and load-bearing capacity can be customized according to customer needs to meet the personalized demands of different application scenarios.

Integrated countertop design, stable and reliable: With an integrated countertop design, combined with high-quality linear motors and guide rails, and standardized installation techniques, it ensures outstanding motion accuracy and long-term stable reliability, with excellent Pitch and Yaw precision performance.

High resolution and fine control: The platform is driven by linear motors and has excellent micro-step capabilities. Combined with high-performance controllers, it can achieve sub-micron-level fine positioning, meeting the pursuit of ultimate precision.

No reserved center hole, strong load-bearing capacity: The design without reserved center holes can adapt to larger-sized application scenarios and has a strong load-bearing capacity.

Ultra-quiet operation, creating a comfortable environment: The ultra-quiet displacement stage is suitable for noise-sensitive laboratory environments and high-performance industrial sites.

Powerful software support and easy operation: Free standard SDK, supporting multiple development languages (C/C++, C#, Matlab, LabVIEW, etc.) in Windows and Linux environments, facilitating users' secondary development and system integration.

High-performance controller, achieving complex motion: The controller supports circular interpolation, linear interpolation, position memory and arbitrary graphic import, which can meet various complex motion control requirements. (Optional)

Flexible communication and seamless connection: Optional EtherCAT bus control is available to achieve high-speed and stable data transmission.

Product application:

2D Scan, Machine Vision, Defect Detection, Industrial Equipment

Performance measurement:

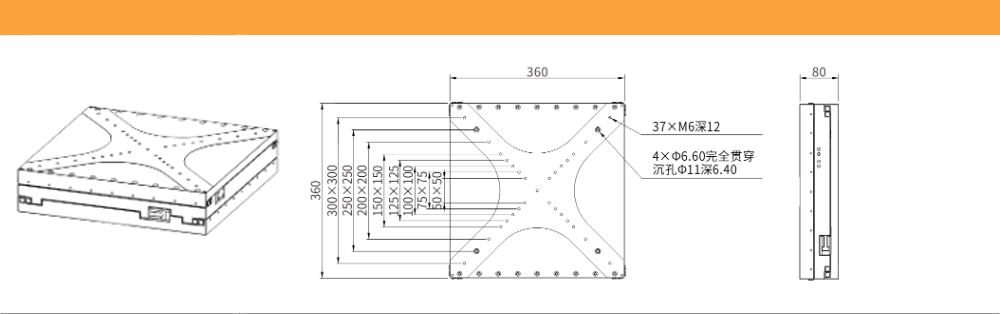

Product size:

We are glad that you can cooperate with us. In order to save your time, when selecting products, please check the parameters or communicate with our sales team to avoid delaying your construction period due to the inconsistency between the parameters and your use requirements. We thank you again for your support.