Product Description:

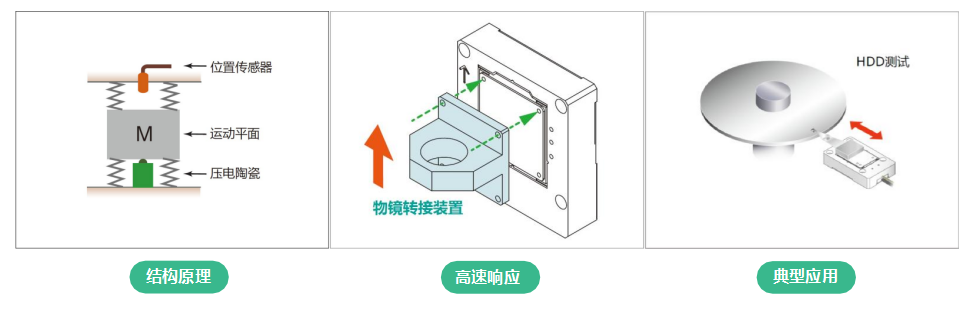

1.igh-speed movement, direct drive

2. Compact design

3. Closed-loop control

4. Stackable for XY movement

The X-axis nano-positioning linear displacement stage is a linear displacement stage based on piezoelectric control. The stroke includes 12/30/45/60 μm and customizable other stroke versions.

The H45 series piezoelectric nano-displacement stage uses high-reliability multi-layer low-voltage piezoelectric stacked ceramics as the driving element. The solid-state flexible guiding system optimized by finite element analysis ensures perfect translational motion. The platform adopts a frictionless flexible mechanism. The piezoelectric displacement stage does not require maintenance, has no wear, and has fast response and stable performance, making it suitable for dynamic processes such as high-frequency error compensation, tracking, rapid stepping, or continuous scanning, etc. The closed-loop version has a high-resolution strain gauge type position sensor, which can achieve high-precision and repeatable motion and can also compensate for the creep of piezoelectric ceramics. The sensor adopts a full closed-loop bridge design. It can operate in either open-loop or closed-loop control.

The fixation of the piezoelectric platform is achieved through the threaded holes on the moving surface and the base plate. If it is to be installed onto an optical platform with a standard grid or other components, a adapter plate should be used for connection. During the fastening process, excessive bending moment loads and lateral forces acting between the moving surface and the housing should be avoided, as these external forces may damage the displacement stage.

Optional features: Customizable transfer tooling, selectable PZT & Sensor connectors and cable lengths, optional closed-loop (SGS) position feedback system, configurable grouping, customizable other travel ranges.

Application fields: Scanning microscope, fiber end face inspection, interferometer, measurement technology, 3D solder paste inspection, photonics, fiber positioning, interference, nano-lithography, nano-positioning, electrochemical addition.

Product parameters:

| Specification Model 1 | H45-01 | H45-030 | H45-045 | H45-060 | Tolerance 8 |

| Motion Axis | X | X | X | X | - |

| Integrated Sensor | SGS | SGS | SGS | SGS | - |

| Nominal travel range 2(@0~+120V) | 12 μm | 30 μm | 45 μm | 60 μm | ±5% |

| Maximum travel range 2(@-20~+150V) | 20 μm | 40 μm | 60 μm | 80 μm | ±20% |

| Resolution 3 | 0.1 nm | 0.3 nm | 0.4 nm | 0.5 nm | typ. |

| Minimum movement step size 4 | 0.4 nm | 1.0 nm | 1.5 nm | 2.0 nm | typ. |

| Linear error | 0.02%~0.05% | 0.02%~0.05% | 0.02%~0.05% | 0.02%~0.05% | typ. |

| Repeatability positioning accuracy (full travel) | 0.05% | 0.05% | 0.05% | 0.05% | typ. |

| Angular sway deviation (pitch/yaw/roll) | 10 μrad | 10 μrad | 10 μrad | 10 μrad | typ. |

| Load-bearing capacity 5 | 50 N | 50 N | 50 N | 50 N | Max. |

| Resonance frequency (0g) | 3000 Hz | 2500 Hz | 2000 Hz | 1500 Hz | ±20% |

| Directional stiffness of movement | 40 N/μm | 40 N/μm | 40 N/μm | 40 N/μm | ±20% |

| Directional thrust/pull of movement | 450N / 100N | 450N / 100N | 450N / 100N | 450N / 100N | ±20% |

| Drive mechanism | PZT | PZT | PZT | PZT | - |

| Operating temperature range | -20~+80 ℃ | -20~+80 ℃ | -20~+80 ℃ | -20~+80 ℃ | typ. |

| Cable length 6 | 1.5 m | 1.5 m | 1.5 m | 1.5 m | ±10mm |

| Hollow dimension | - | - | - | - | - |

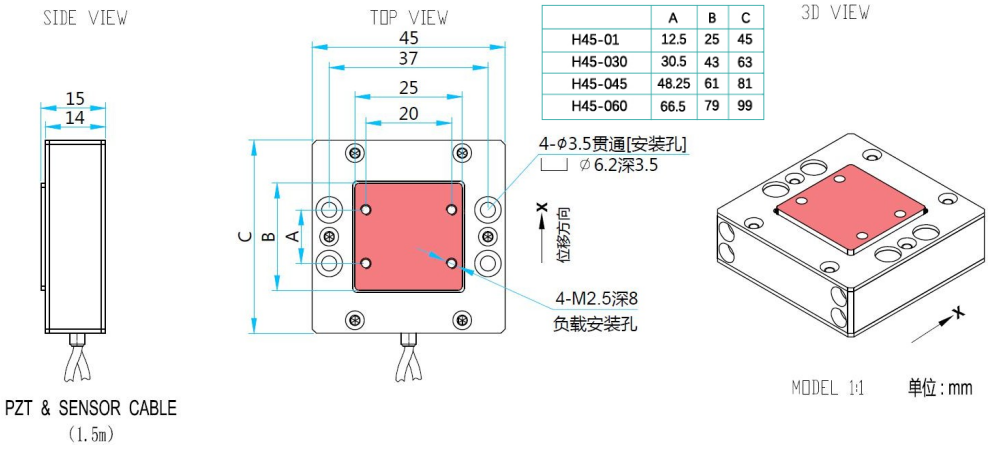

| Overall dimensions (length × width × height) | 45 ×45 ×15 mm | 45 ×63 ×15 mm | 45 ×81 ×15 mm | 45 ×99 ×15 mm | - |

| weight 7 | 65 g | 100 g | 150 g | 200 g | ±5% |

| PZT & Sensor Connector | LEMO | LEMO | LEMO | LEMO | - |

| Material of the body | Aluminum | Aluminum | Aluminum | Aluminum | - |

Note: All specification parameters are measured at room temperature (22°C ± 3°C). For more information, please contact us. "-" in the table indicates that it is not applicable.

1.The suffix "-S" indicates a closed loop and is equipped with an internal position sensor. The open-loop suffix does not have "-S" and does not have data on linear error and repeatability.

2. The maximum driving voltage ranges from -20V to +150V. For long-term use with high reliability, it is recommended to set the driving voltage between 0V and +120V. For larger stroke, please consult. The factory-provided value is the nominal stroke.

3. Resolution refers to positioning noise. Since the piezoelectric ceramic nano-positioning system has no friction, the system resolution is only limited by the amplifier noise and the measurement technology. Usually, the RMS (1σ) value is used for measurement and specification. The closed-loop resolution is the combination of sensor noise, driver electronic noise, and command noise, etc.

4. It refers to the minimum step size value of the piezoelectric platform that can be moved as measured by the interferometer. This value is mainly determined by the DAC resolution of the piezoelectric controller. In the best case, the displacement step size value corresponding to 16-Bit in the parameter table is the optimal value.

5. Axial load. For higher loads, please consult. Be aware that exceeding the nominal load can cause damage to the flexible mechanism.

6. For longer cable lengths, please consult.

7. The weight of the platform does not include the weight of the cables and connectors.

8. In the tolerance values, "Max." represents the maximum value; "typ." indicates the typical standard data value, and the actual measured data value will be provided in the inspection report.

Product size:

We are glad that you can cooperate with us.,As the journey is far away, please be sure to see the parameters or communicate with our sales when selecting the product, Avoid buying wrong products to delay your use.