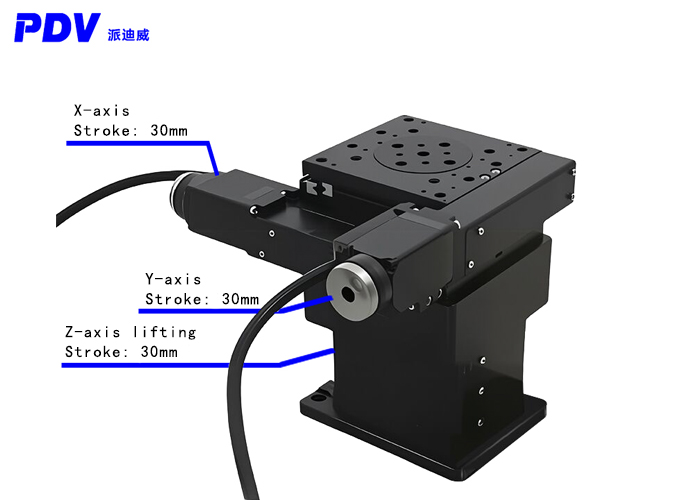

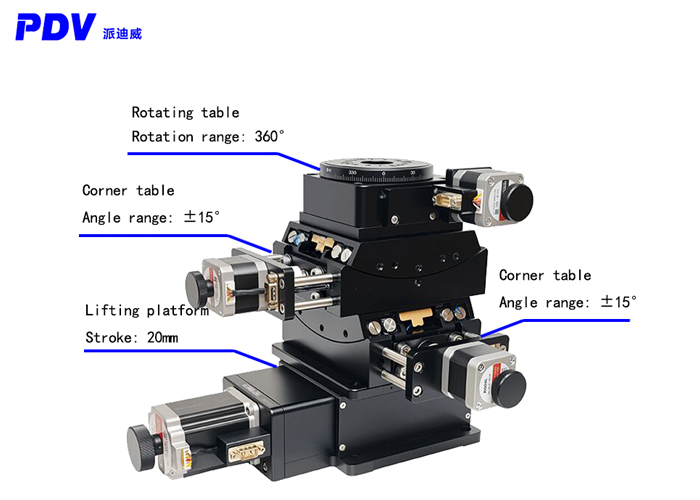

Three - dimensional adjustment table with different stroke combinations can be selected。

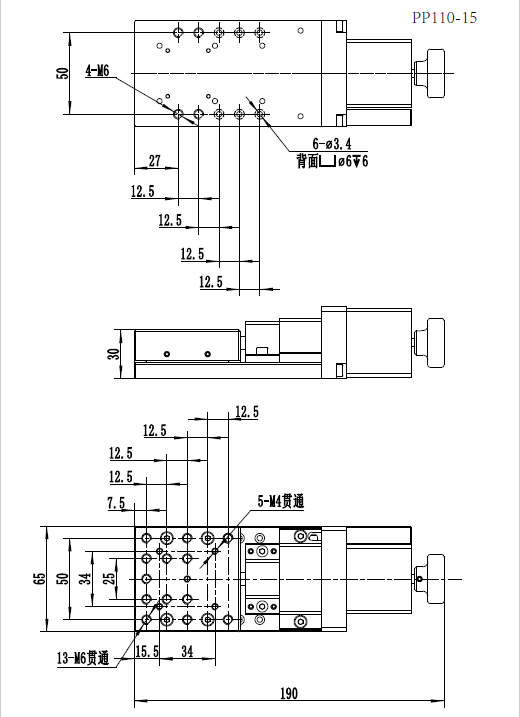

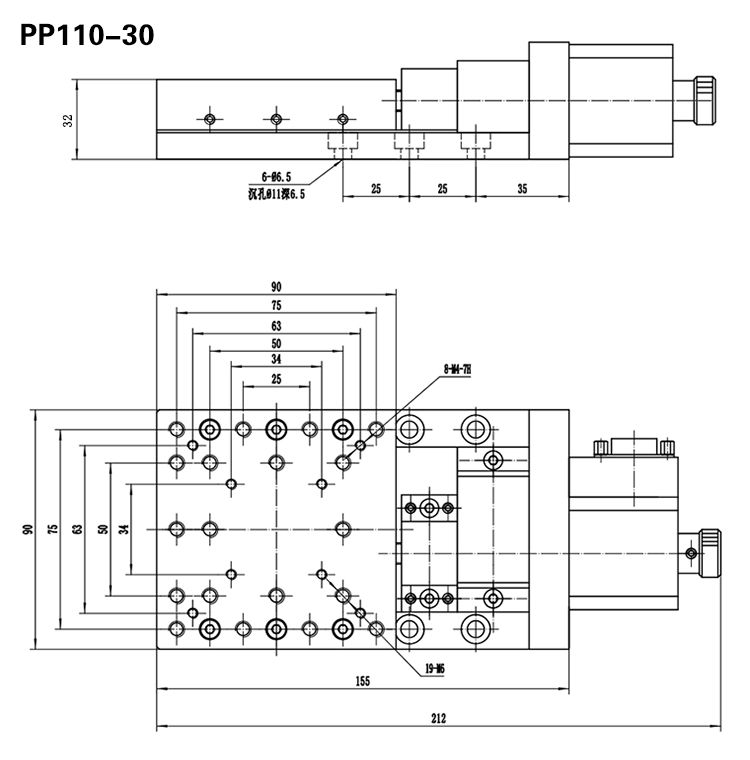

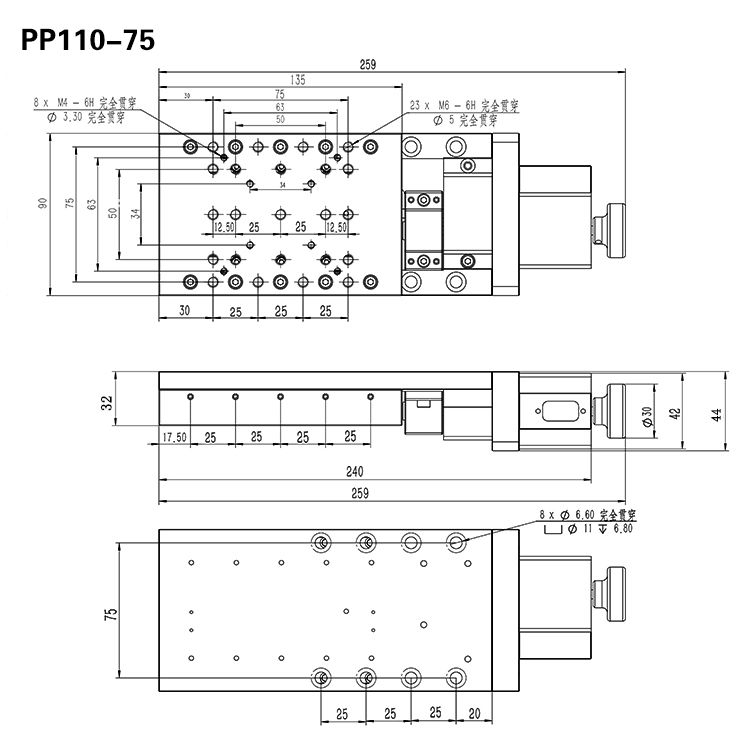

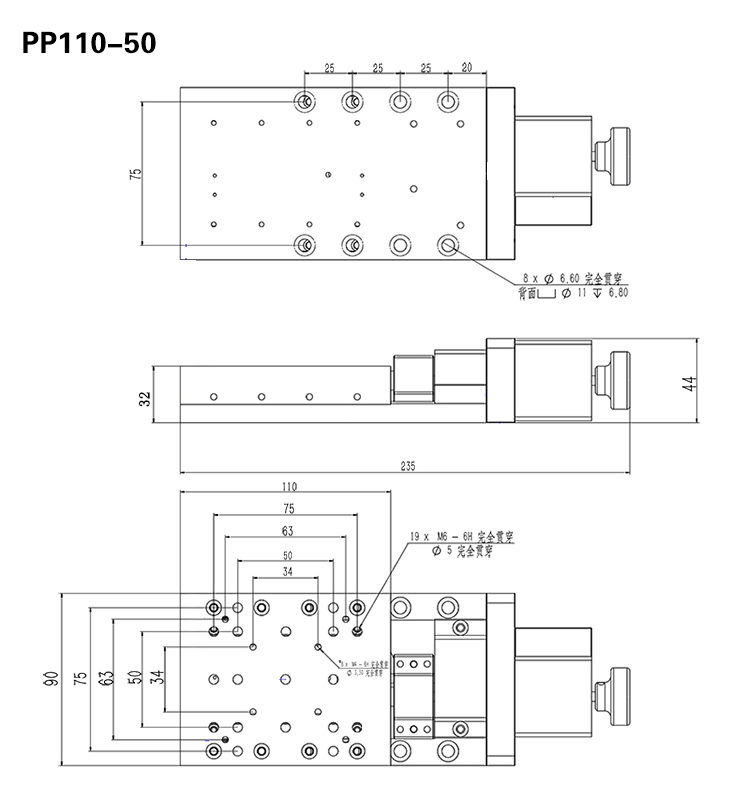

Model Number | PP110-15 | PP110-30 | PP110-50 | PP110-75 | |

Structure | Travel | 15 Mm | 30mm | 50 Mm | 75 Mm |

Platform Size | 65×65mm | 90×90mm | 90×110mm | 90×110mm | |

Screw Specification | Grinding Screw Rod (Lead 1 Mm) | ||||

Guide | Precision Cross Roller Guide | ||||

Stepper Motor (1.8 °) | 42Byg | ||||

Main Material | Aluminium Alloy | ||||

Surface Treatment | Anodizing Blackening | ||||

Table Bearing | 5kg | 15kg | 20 Kg | ||

Weight | 0.93kg | 1.25kg | 1.4kg | 1.7kg | |

Accuracy | Resolving Power | 5μ/ Pulse (No Subdivision) |

5μ((No Subdivision) | ||

Speed | 5mm/sec | 10mm/sec | |||

Repeat Positioning Accuracy | 2μ | 5μ | |||

Positioning Accuracy | 10μ | 10μ | |||

Straightness | 5μ | 8μ | 12μ | ||

Motion Parallelism | 20μ | 15μ | |||

Pitch | 30″ | 25″ | |||

Yaw | 25″ | 20″ | |||

Return Clearance | 2μ | 2μ | |||

Lose Step | 2μ | 2μ | |||

Accessory | Brake Function (-Z), Grating Scales (-G), Servo Motor (-D) | ||||

Product Features:

■ Standard step motor 9 pin interface, the company's motion controller can realize automatic control.

■ The product structure is small and light, suitable for light load, low speed use, scientific test use.

■ High quality fine grinding screw drive, small lead, same fine fraction can achieve high resolution.

■ Ingenious design of empty back nut structure, can make the clearance of grinding screw pair to Z small.

■ The guide rail adopts cross-roller guide rail, which is comfortable for movement. It has the function of adjusting the preload force of the guide rail laterally and eliminating the gap. It can be used in multi-dimensional combination.

■ Fine grinding of the bottom plate and reasonable guide rail fixation method reduce the pitch and deflection of the electric platform, so that the straightness and parallelism of the movement are greatly improved.

■ The stepper motor and the grinding lead rod are connected by the high-quality elastic coupling, the transmission is synchronized, the offset performance is good, reduces the eccentric disturbance and the noise is small.

■ Equipped with handwheel for easy debugging.

■ Limit switches are installed at both ends to facilitate accurate positioning and protection of products.

■ The base has threaded holes and through holes with standard hole spacing for easy installation and fixation.

Product size diagram:

We'd be happy to have you working with us. In order to save your time, when choosing products, please check the parameters or communicate with our sales, to avoid the product you buy, because the parameters are not consistent with your use requirements, delay your construction schedule. We thank you again for your support.